Powdercoating

The Powdercoating Process

Pentland Powdercoating offer powder coating services for a huge range of different items. Powdercoating can be done to replace painting on almost any metal object. Powder coating offers a far more resilient finish that lasts longer than normal painting.

If you think powdercoating would benefit an item you have, please call us or send us a photograph or photographs by e-mail and we will respond within one working day.

We have powdercoated many different items that from the radiators to garden ornaments. The finish powder coating offers that is the same as wet painting but far more resistant to damage and corrosion.

If you are interested in learning more about the powdercoating process please click here for a detailed outline of how this works.

The Powdercoating Process

Powdercoating is the technique of applying dry paint to a part. The final cured coating is the same as a 2-pack wet paint.

In normal wet painting such as house paints, the solids are in suspension in a liquid carrier, which must evaporate before the solid paint coating is produced.

In powdercoating, the powdered paint may be applied by either of two techniques.

The item is lowered into a fluidised bed of the powder, which may or may not be electrostatically charged, or The powdered paint is electrostatically charged and sprayed onto the part.

Thermoplastic powders that will remelt when heated, and Thermosetting powders that will not remelt upon reheating. During the curing process (in the oven) a chemical cross-linking reaction is triggered at the curing temperature and it is this chemical reaction which gives the powder coating many of its desirable properties.

Preparation

The basis of any good coating is preparation. The vast majority of powdercoating failures can be traced to a lack of a suitable preparation.

The preparation treatment is different for different materials.

Oils and greases are removed in weak alkali or neutral detergent solutions and the surface is etched to remove heavy oxides. After rinsing, the aluminium is dipped into a chromate or phosphate solution to form a conversion coating on the aluminium. This film is chemically attached to the aluminium. After rinsing the aluminium is finally rinsed in demineralised water. Some non-chrome, dried in place pre-treatment is beginning to come onto the market; currently, these are not recommended for exterior applications.

The conversion coating has two functions:

It presents a surface to the powder which favours adhesion more than the oxides that form very readily on aluminium surfaces, and it reduces the incidence of under film corrosion, which may occur at holidays in the coating.

The use of demineralised water reduces the presence of chemical salts on the aluminium surface. These salts have been found to cause filiform corrosion in humid conditions.

For steel the preparation for interior applications may be: Clean, Rinse, Derust, Rinse, Iron Phosphate, Rinse, Acidulated Rinse

For exterior applications: Clean Rinse, EtchRinse, Grain Refine, Zinc Phosphate, Rinse, Acidulated Rinse

The grain refiner is used after acid cleaning of steel surfaces and before zinc phosphating, otherwise the zinc phosphate coatings produced will be very coarse with low adhesion.

The powder coating applied to a coarse phosphate will produce rough coatings (a little like “sandpaper”) and possess low adhesion.

For hot dipped galvanized coatings, which have been stored for more than about 4 hours before powder coating, the following process is necessary for exterior applications. Clean, Rinse, EtchRinse, Grain Refiner, Rinse, Zinc Phosphate, Acidulated Rinse

The etch is required to remove the zinc corrosion products which begin to form almost immediately the zinc is removed from the galvanizing kettle. The grain refiner ensures a fine phosphate is produced.

How is it done — electrostatic spray?

The powder is applied with an electrostatic spray gun to a part that is at earth (or ground) potential.

Before the powder is sent to the gun it is fluidised: to separate the individual grains of powder and so improve the electrostatic charge that can be applied to the powder and so that the powder flows more easily to the gun.

Because the powder particles are electrostatically charged, the powder wraps around to the back of the part as it passes by towards the air offtake system. By collecting the powder, which passes by the job, and filtering it, the efficiency of the process can be increased to 95% material usage.

The powder will remain attached to the part as long as some of the electrostatic charge remains on the powder. To obtain the final solid, tough, abrasion resistant coating the powder coated items are placed in an oven and heated to temperatures that range from 160 to 210 degrees C (depending on the powder).

Under the influence of heat a thermosetting powder goes through 4 stages to full cure.

MELT, FLOW, GEL, CURE

The final coating is continuous and will vary from high gloss to flat matt depending on the design of the powder by the supplier.

Powder coating guns

There are at east three types of electrostatic guns in use:

Corona charging guns where electric power is used to generate the electrostatic charge. Corona guns are either internal or external charging.

Tribo charging guns where the electrostatic charge is generated by friction between the powder and the gun barrel.

“Bell” charging guns where the powder is charged by being “flung” from the perimeter of the “bell”

Not all powder is applied using guns. One system makes use of electrostatic tunnels.

How is colour introduced?

Colour is added to powder coatings during the manufacturing process, ie before the powder reaches the powder coater. There is little that can be done to change the colour consistently, once the powder leaves the manufacturing plant.

Why powder coat?

Powder coating produces a high specification coating which is relatively hard, abrasion resistant (depending on the specification) and tough. Thin powder coatings can be bent but this is not recommended for exterior applications.

The choice of colours and finishes is almost limitless, if you have the time and money to have the powder produced by the powder manufacturer.

Powder coatings can be applied over a wide range of thickness. The new Australian Standard, “AS/NZS 4506 – Thermoset powder coatings”, will recommend 25 micron minimum for mild interior applications and up to 60 micron minimum for exterior applications. Care must be exercised when quoting minimum thickness because some powder will not give “coverage” below 60 or even 80 micron. “Coverage” is the ability to cover the colour of the metal with the powder. Some of the white colours require about 75 micron to give full “coverage”. One of the orange colours must be applied at 80 micron.

Colour matching is quite acceptable batch to batch.

Installations and maintenance

During installations, the powder coating should be protected from damage due to abrasion and materials of construction such as mortar and brick cleaning chemicals.

Once installed, maintaining the initial appearance of a powder coating is a simple matter. The soot and grime which builds up on surfaces from time to time contains moisture and salts which will adversely affect the powder coating and must be removed. Powder coatings should be washed down regularly (at least once each 6 months in less severe applications and more often in marine and industrial environments). The coating should be washed down with soapy water — use a neutral detergent — and rinsed off with clean water.

When powder coated items are installed without damage to the powder coating and they are maintained regularly, they should be relatively permanent. The correctly applied coating, although not metallurgically bonded to the metal will not crack, chip or peel as with conventional paint films.

Alloy wheel repairs & refurbishment

Wheels start from an incredible £45.00 +VAT

Our wheel refurbishment starts from £45.00 + VAT for bare 19″ wheels and £50.00 + VAT for 18″ wheels with tyres. We can remove and re-balance your tyres and replace old ones too. If you wish to leave your car with us, we can loan our courtesy car for the day if you are 21 and over and you can collect your car with your newly refurbished wheels by 4pm the same day!

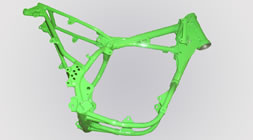

Motorcycle frames & wheels

Prices start at £80 +VAT

We can also refurbish or repair your swing arm and wheels. We will take a corroded frame, protect the bearing areas and sandblast the old paint and corrosion off, make any repairs that may be necessary then, powdercoat it in any colour of your choice. The end result is as good as new. Our prices that will bring a smile to your face every time you look at your bike.